APPLICATIONS > BY INDUSTRY

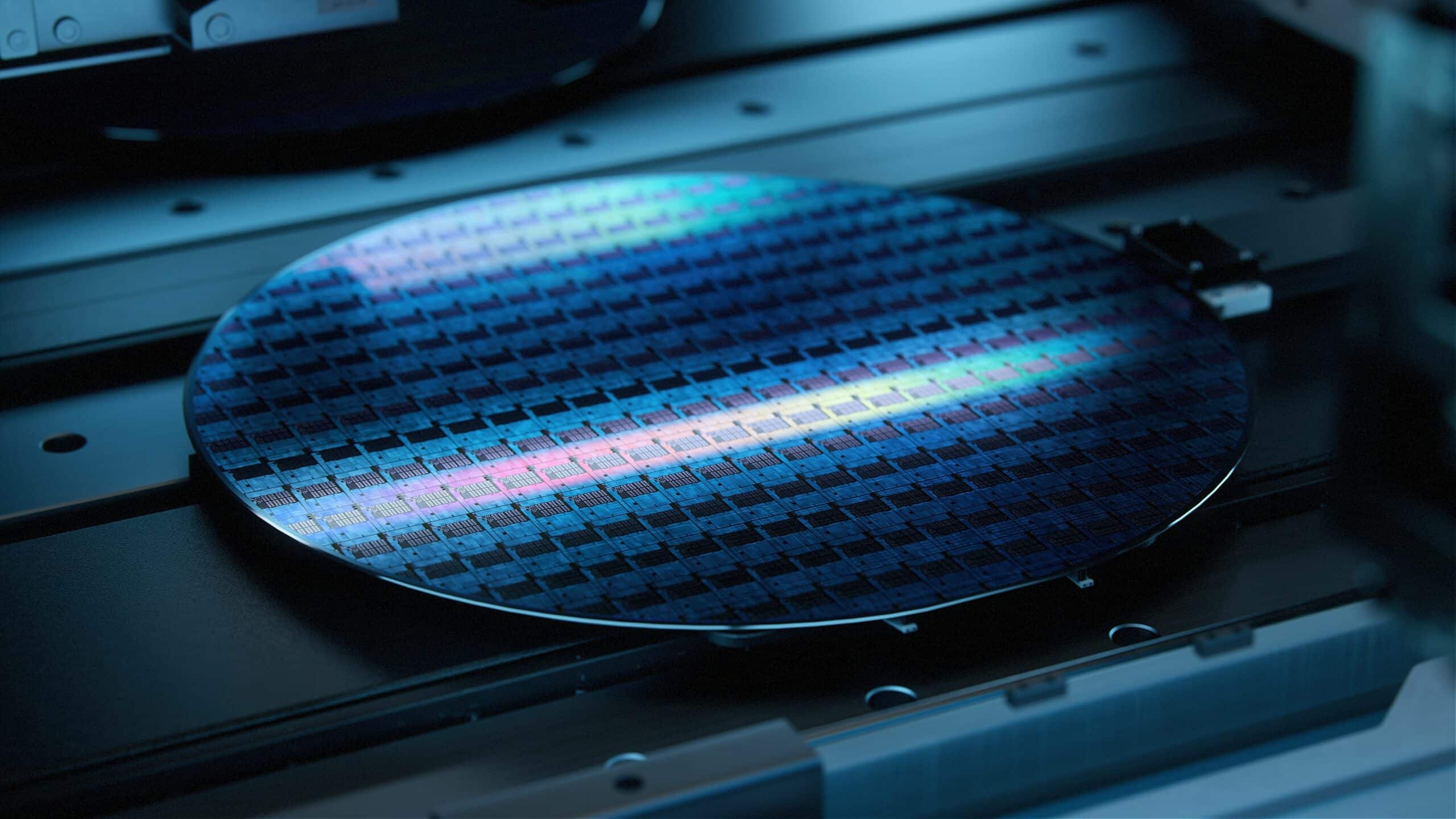

Semiconductors Manufacturing

Learn more about how Beamonics can help semiconductors manufacturers with gas analysis. Read our case study about how we helped improve quality in semiconductor production in South Korea.

CASE STUDY

Semiconductor Manufacturing

Challenge

Semiconductor production is highly sensitive to oxidation, making continuous oxygen analysis crucial for quality. Even trace oxygen can cause defects. Stringent monitoring is needed to keep oxygen levels minimal, but traditional systems lack the sensitivity and real-time response required to protect these delicate materials.

Our Solution

Our solution provides a cutting-edge solution that met the stringent requirements of continuously measuring extremely low levels of oxygen in real-time.

Key Results

Our solution significantly improves semiconductor production quality with highly sensitive, real-time oxygen analysis. It detects minimal oxygen levels instantly, integrates seamlessly, and operates without disrupting manufacturing. Ideal for the global semiconductor industry, its self-calibrating, maintenance-free design offers reliable, cost-effective monitoring for critical components.

OUR SOLUTION

Key Advantages

Real-Time Monitoring

BeamStack measures concentrations up to ten times per second, providing continuous real-time data. This high sensitivity ensures that even the slightest increases in oxidation levels are detected immediately.

Automatic Alerts

The system integrates with existing monitoring frameworks, providing automatic, redundant alerts if oxygen levels exceed thresholds, ensuring prompt issue resolution and minimizing damage risks.

Uninterrupted Monitoring

The solution operates seamlessly in the background, continuously monitoring oxygen levels without disrupting semiconductor manufacturing, crucial for maintaining efficiency and quality.

Transmission Adaptibility

Even with varying transmission levels, the BeamStack maintains accurate measurements. This adaptability ensures reliable performance under different operational conditions, providing consistent analysis.

Self-Calibrating

One of the standout features of the Beamonics system is its self-calibrating capability. The system automatically adjusts its settings to maintain optimal performance.

Maintenance-Free

The BeamStack system eliminates the need for regular cleaning or additional maintenance. This feature not only reduces operational costs but also ensures uninterrupted process analysis.

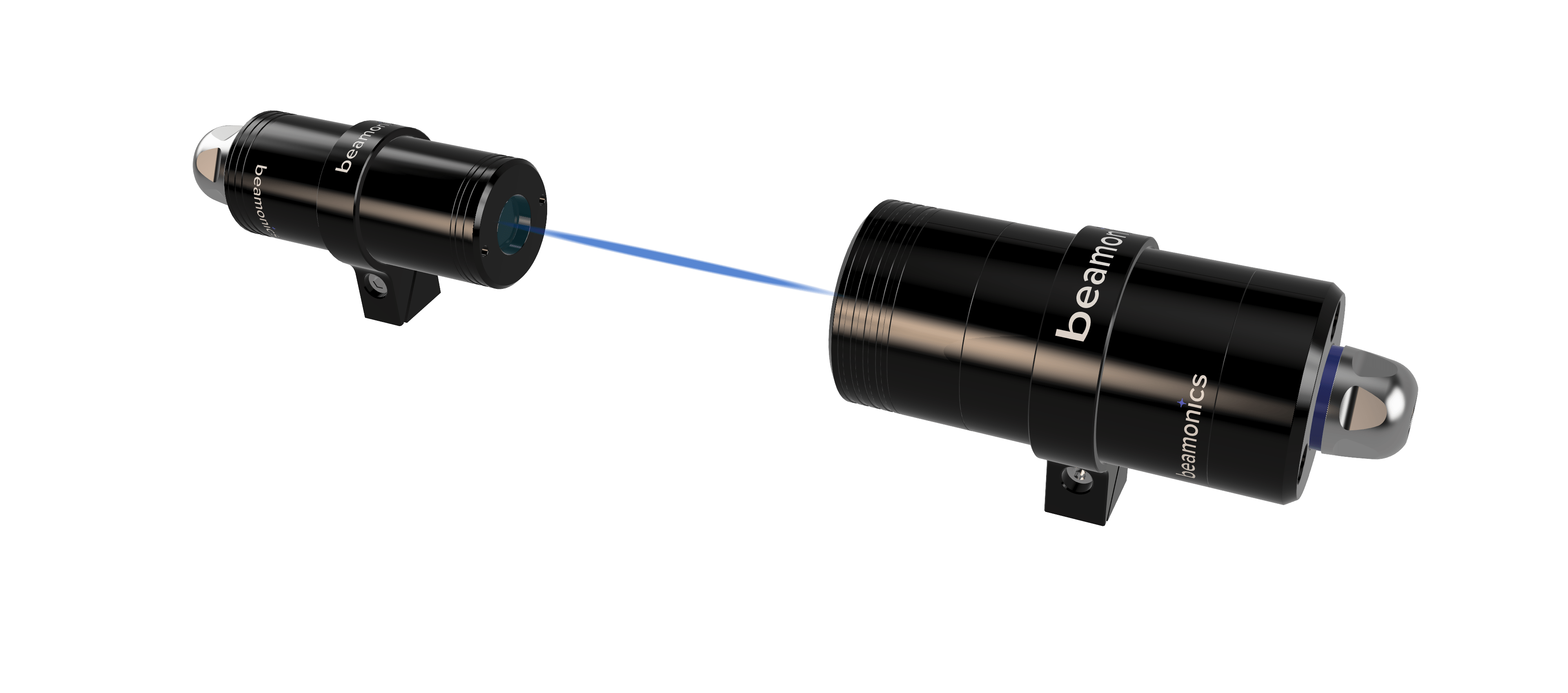

GAS ANALYZERS

Our Products

Why Implement TDLAS?

Industries handling gas monitoring face challenges like calibration demands, limited sensitivity, and high maintenance, especially in harsh environments. Traditional analyzers can disrupt operations and compromise safety when dealing with hazardous gases.

Beamonics’ gas analyzers — based on Tunable Diode Laser Absorption Spectroscopy (TDLAS)—solve these issues by providing highly sensitive, and calibration-free gas analysis.

- BeamCell provides an accurate extractive gas analysis, delivering results at parts-per-billion (PPB) levels. This system is self-referencing, reducing calibration needs and enabling continuous operation even in rugged conditions.

- BeamStack is a versatile turnkey gas analyzer that integrates seamlessly with industrial PLC systems. Its low-maintenance, robust design makes it ideal for challenging environments, with options for situations requiring flexibility.

- BeamSight offers a unique solution for remote, stand-off gas analysis up to 100 meters away, ideal for monitoring hazardous areas safely. Its portability and alignment-free setup allow for easy deployment in both stationary and mobile configurations.

TDLAS-based solutions empower you to conduct precise, reliable gas analysis with no maintenance, enabling safer, more efficient, and compliant operations across sectors.

BENEFITS AND FEAUTURES

Why Our Products Are Different

Precision Excellence

Real-time Insights

>1000 unique analyses per second, alerting you only when necessary.

Easily Adaptable

Real-time measurement and results in your preferred format.

Low Concentrations

Made in Sweden

Robust, sustainable & replaceable components for long-lasting use.

Ready to Use

Compact and turnkey devices, operational withinin seconds.

OUR TECHNOLOGY

How Our Technology Works

1. Laser Emission

A tunable diode laser emits specific colors (wavelengths) of light that is directed through the gas sample.

2. Absorption Measurement

As the laser passes through the gas, molecules absorb some light, which is then measured and recorded.

3. Concentration Calculation

The absorption is analyzed to determine the gas concentration, providing precise, real-time measurements.

Frequently Asked Questions

What gases can be analyzed?

We cover many common process gases and technically all gases that absorb light in the spectrum from 650 nm to 2.5 μm. Including, but not limited to: Methane (CH₄), Oxygen (O₂), Carbon Dioxide (CO₂), Carbon Monoxide (CO), Hydrogen Fluoride (HF), Ammonia (NH₃), Nitrogen Oxides (NO, N₂O), Water Vapor (H₂O), Hydrogen Sulfide (H₂S), and Hydrogen Chloride (HCl).

Are your instruments sensitive to surrounding light?

No, our instruments are designed to only analyze the light at a specific wavelength. Therefore, the surrounding can be in darkness, daylight, fluorescent light or other artificial light sources.

Are your products certified?

Our products are both patented and carry the CE mark, fulfilling a wide range of applications where they are currently deployed. If you have specific requirements, please contact us and we will look into it.

When can we have the solution up and running?

Our products offer an out-of-the-box experience operational within seconds, but we always recommend integration of the product into specific processes to ensure optimal performance. For the most common process gases, we have a turnkey solution ready to deliver to the integrator within weeks. For more unusual gases or applications, it may take some additional time, primarily due to the availability of components, especially the laser. Please contact us for guidance, whether you are an end-user or an integrator who wants to become a partner, we have turnkey solutions ready to be delivered within weeks.

How is the price level compared to other gas analyzers?

The price level depends on the application and the need for integration. However, in general, the ROI is very competitive compared to other gas analyzers on the market. We offer real-time data with higher accuracy in tough conditions, minimal maintenance costs, and long-lasting products made with high-quality and replaceable components.

TDLAS seems great, but I need multiple sensors for point measurements in several positions in my facility, do you have a solution for this that can be competitive?

Yes, we can provide a solution where gas is extracted from each position where you need to measure, and the gas is analyzed in a central unit. Due to the speed of the TDLAS, even sampling of over 30 points can be done in tens of seconds.

What kind of support can I expect from you?

As a partner, you will receive support directly from the inventors, who are dedicated to creating the world's best laser diode gas analyzer. We are committed to working closely with our partners to deliver the best solution for the end-user.

There are several TDLAS solutions on the market, why choose Beamonics?

Most solutions on the market are based on generic platforms. As the inventors of our proprietary technology platform, we have the expertise to adapt it for smooth user operation and to challenging and unique applications. We are committed to providing a solution that is built to last, offering outstanding performance and reliability tailored to your needs.

It seems like an innovative solution, but is it proven?

Our solution is both unique and proven. With over a hundred deployments operating seamlessly and continuously, often in tough conditions, our systems are supported by global partners and have demonstrated their reliability.